State of the Edge 2020

Ignition Edge has come a long way since it was first introduced. There are now 5 different versions of Ignition Edge to give you the flexibility to use it in almost any situation. With exciting things coming down the pipe like OEE Edge from Sepasoft, it is a great time to look into Edge solutions if you haven’t already.

Following the order of the packages on the Inductive Automation site, let’s dive into each option, give an overview of what it does, tell you when and why you would want to use it, and help you decide if Ignition Edge is right for you.

On Deck Production Runs

Corso Systems shows how On Deck Production Runs are a useful approach to manufacturing. because. Staging an order before it is run on the line can allow for moving raw materials, swapping dies or inserts on a machine for new parts, cleaning cycles, or an allergen flush to increase productivity and reduce downtime.

How to Program Lead/Lag Pumping in Ignition

Corso Systems describes how to approach lead/lag/standby pumping schemes from a control perspective and how to quickly integrate them into Ignition for operator control. Lead/lag/standby schemes are standard in pumping applications, especially in water/wastewater. They allow a system to operate at low capacity, ramp up to meet increased demand, and spread the operational load across multiple pumps to reduce maintenance costs.

Confectionery Process Automation and OEE Tracking

A leading chocolate manufacturer in Pennsylvania needed to upgrade and more fully automate one of their production lines. This coincided with an MES Upgrade and allowed the production line to be fully integrated into the production scheduling and other systems implemented as part of the MES project.

Adding Text Annotations on Ignition Report Trends

Corso Systems explains how to use scripting on an Ignition trend chart to annotate a value. Display when an important value occured and what that value was - and more. While this functionality is not directly built into the reporting module, it’s easy using scripting on the trend component.

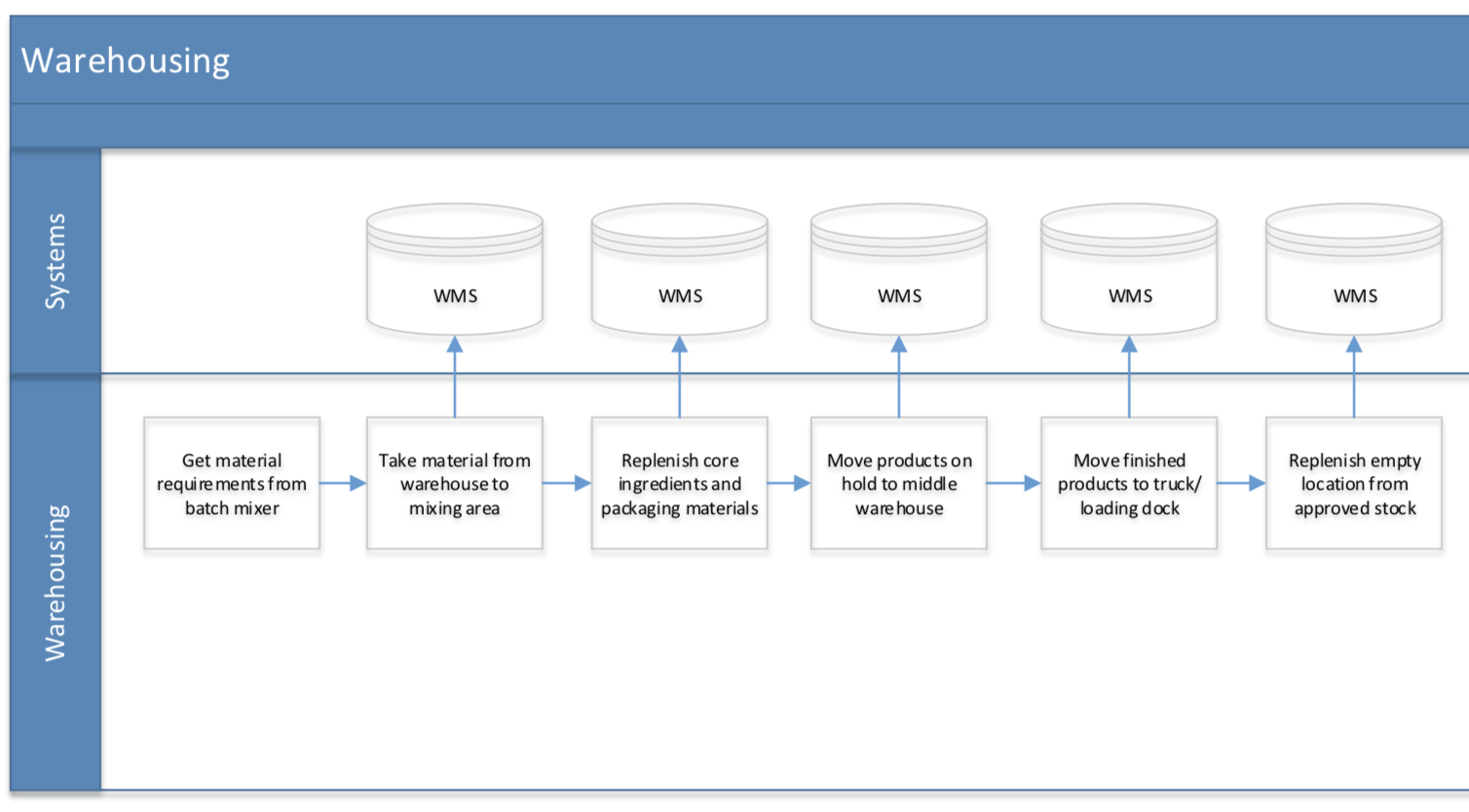

Confectionery Manufacturing Execution System

A leading chocolate manufacturer in Pennsylvania needed a manufacturing execution system to tie together 9 different business systems into a single software package. This included customer order management, shipping and receiving, warehouse management, track and traceability, SPC, and in-process inventory tracking. Corso delivered a solution with Inductive Automation’s Ignition platform and helped take the company to the next level.

10 Torr Distilling and Brewing Process Automation

10 Torr Distilling and Brewing company built a brand new brewery and distilling operation in Reno NV. Corso Systems used Inductive Automation’s Ignition to create a fully automated control system for their brewing and distilling operations.

Pet Food Scheduling, OEE, and Maintenance Management System

A leading manufacturer of high-quality, single-source recipe pet food with facilities across North America required a production scheduling management and OEE tracking system for a greenfield Facility. Ignition by Inductive Automation along with the OEE and Scheduling module from Sepasoft was chosen for the SCADA and MES platform, and the required functionality was developed by Corso Systems and tested with various OEM manufacturers on the various production and packaging lines at the facility.

Automated Furnace Loading and Unloading Manipulator

A leading aerospace company has a production line consisting of multiple furnaces and quench pits capable of heat treating multiple batches of parts at a time. Their current hardware had reached the end of its life and was ready to be upgraded to modern standards. A new manipulator with full servo control, updated safety and interlock logic, and touchscreen operation was made to replace the old unit.

Oil & Gas OSI PI to Canary Conversion

A large oil and natural gas company had been using OSI PI requiring extensive overhead for support. They wanted to be able to better manage and develop the system to meet their needs, including allowing integrator support to get away from a single source of development resources. After a market analysis it was determined Canary Labs Historian was the best solution for this project.

Jaxon Renewables Case Study

Corso Systems worked with Jaxon Energy on new facility that was a complete overhaul and upgrade to an existing facility. This plant made renewable diesel fuel from vegetable oils. With total plant control and visibility in mind, Corso wrote PLC logic, designed the HMI screens, and deployed a process historian. Allen Bradley PLCs and FactoryTalk View SE provided the backbone of the control system.

Upgrading to Ignition 8.0 - Making the Leap

Corso Systems shares their experiences with a first large scale 7.9 to 8.0 Inductive Automation Ignition upgrade. While it went smoothly, there were a couple of hurdles. Find out how we solved the issues and what to watch out for when you perform an Ignition upgrade.