SCADA and ERP Integrations

If a Supervisory Control and Data Acquisition (SCADA) system is the tool you use to manage a process control system, an Enterprise Resource Planning (ERP) system is the tool you use to run a business.

For manufacturing companies, combining these two systems can have a compounding effect on your overall ability to make what your customers need—exactly when it needs to roll off the line.

What is an ERP System?

An ERP system is the glue holding your business together. ERP systems help you manage business processes much like SCADA helps you manage manufacturing processes.

ERP systems combine many different business data sources together to create a centralized system to manage your operation. Typically, these data sources include customer information systems, order management, shipping and receiving, warehouse management, production scheduling, inventory of both raw materials and finished products. ERP systems can address quality control systems, sales, and training. For instance, all the inputs to an ERP system can more effectively manage potential risks like supply chain disruption, changes in customer ordering patterns, and quality control issues.

Since ERP systems have been around for a number of decades, there are a few major players. Microsoft Dynamics, Oracle, SAP, and NetSuite across manufacturing, and specialized ERP systems like JustFood provide functionality designed for food and beverage manufacturers. These systems can be deployed in a variety of ways, including on-premise, cloud-based, or a mixture of the two. At its core, an ERP system is a front end for interacting with many different databases. Each of these databases will contain information relevant to a portion of your business, and ERP helps you integrate their information to make better informed decisions.

As you look deeper into ERP systems—either to implement them for the first time, or to take stock of what’s already at your disposal—you will start to see a lot of overlap with the information needs at the plant floor. You’ll begin to notice how your process control system will work as another input into the ERP system.

What is a SCADA System?

SCADA systems give you a detailed view into your manufacturing operation and process controls. For some examples and a detailed look at SCADA in general please check out our SCADA Guide.

At their foundation, SCADA systems give you two main benefits:

They track how your process is doing over time.

They provide the information and interface you need to make adjustments to the process.

In addition, you can use alarms about the process to help you keep the plant within desired operating parameters. Trends let you watch how the moment-by-moment decisions your operators are making impact production. Finally, reports and dashboards help you keep your entire organization up to speed on production throughout the day.

There are many SCADA platforms on the market including Aveva (formerly Wonderware), Rockwell’s FactoryTalk View, Siemens various WinCC options, and one of our favorites, Ignition by Inductive Automation. A big benefit of Ignition is that it was designed to be an easy bridge to any database platform you could use in business.

By combining a database-centric SCADA platform with an ERP system—also known as a tool to interact with a lot of databases—you can quickly find many ways to directly impact the bottom line. This information will not necessarily be immediately obvious, but can add up to huge gains in productivity and efficiency.

SCADA and ERP Working Together

There are almost endless benefits from integrating SCADA and ERP systems. It really boils down to having more information to plan what you will produce in the plant, and when—and then using the plant floor as a business unit in the ERP system to keep everyone up to date on what is happening in the factory.

Below are a few examples of low hanging fruit improvements from integrating SCADA and ERP systems.

Inventory

Inventory is an easy win when integrating SCADA and ERP systems. You can track which raw materials are in the warehouse, what you need to produce orders for a given day, and which finished goods will be ready for shipment once production is complete.

If you find you are running low on raw materials, you can quickly shift production to another order before the lack of raw materials stops the line. Then, by tracking real-time production, you can trigger re-ordering materials and parts during production when inventory starts to get towards your order threshold.

You can even clear space in the warehouse by knowing where most of the quantity for an order is located, then producing a smaller batch to fulfill an order.

Scheduling

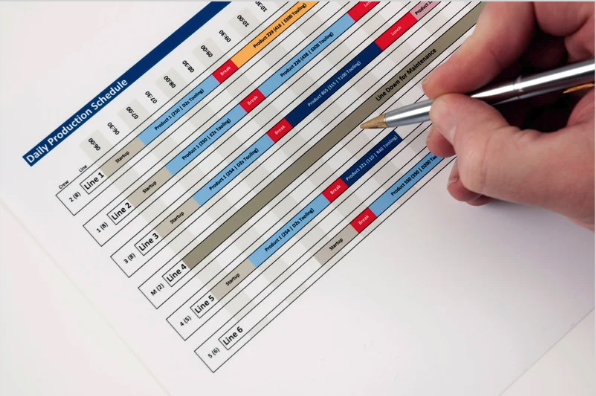

One very common ERP and SCADA integration focuses on Production Scheduling. By using the ERP system to manage customer orders, on hand, and in-transit inventory—along with which materials are in the warehouse—you can build a detailed schedule of what you need to make and when. Exposing what is in the warehouse can shift some of the production requirements if you can fulfill orders from the warehouse first.

When inventory delays or shortages occur, you can quickly pull together a new schedule based on what you have on hand and what you need to make. With a better understanding of your overall order pipeline, you can start towards strategies like just in time manufacturing .

Production scheduling can even have a trickle down effect into shipping and receiving. You maybe be able to more efficiently build shipments to customers by knowing what is coming off the production line and what is being loaded onto a truck in real-time. It might be cheaper to wait until the next day to ship out multiple customer orders if one is coming off the line this afternoon and will fill a truck, instead of sending out a 3/4 full truck today and a 1/4 full one tomorrow morning.

Quality

Many companies include quality control information like lab test results in their ERP system. This can help you get your quality management under control by maintaining a single source of truth for updating your SCADA system once results come in and are entered into the ERP system. In some cases, this is a key component of calculating OEE when real-time quality data isn’t available. During production it is assumed quality is either 100% or 0%, and when the results come in, the quality component of OEE is updated. All of the various reports and dashboards can then be updated for a final OEE tally.

This type of integration can also improve your overall workflow between the warehouse and the plant floor. In many food and beverage processes, raw materials must be tested before they can be released to the floor for production. This can be tracked in the ERP system for managing inventory movement from the warehouse to the plant floor, preventing material pickers from grabbing lots that are still waiting approval. In many cases this provides a great system of checks and balances to help reduce the amount of material movement needed. Production can keep moving at speed if we’ve removed the option for unapproved lots being brought to the plant floor.

Wrapping Up

The benefits of using SCADA and ERP systems together are more numerous than the combinations of other various software platforms. We have barely scratched the surface in this post.

For anyone who isn’t already using SCADA and ERP together, the easiest way to see what is possible is to spend a bit of time thinking through decisions you make on a daily basis and noting where more information would be helpful. Think through where that information might already exist, or what tools you are using when you are making production decisions. You will likely find plenty of options right in front of you.

For a deeper dive into how ERP systems can be used in conjunction with SCADA systems check out our MES Guide for more examples. If you have questions about how you can use SCADA and ERP systems together please reach out and let us know!