Collaborative Manufacturing Technology

Traditionally, there have been two approaches to manufacturing: handmade or fully automated. Handmade items require a skilled craftsperson building products one at a time with a high degree of quality. They will select the best materials, focus on all of the right details, and produce amazing work.

The peak of handmade manufacturing would be like going to restaurant with three Michelin stars to enjoy one of the finest meals in the world.

Fully automated manufacturing is the opposite of handmade. Production is as efficient as possible. A high quality product is defined as a finished product which can be sold—and will not necessarily last for a lifetime. Fully automated processes involve robots, automated equipment, and conveyance systems.

The ideal food related example of fully automated manufacturing would be a fast food enterprise like McDonalds. Process reigns supreme. You will get the same quality of food at any McDonalds in the world, although it might not be the best meal you have ever had.

Neither approach is better or worse overall, they both have their pros and cons. What if there was a third way?

Handmade Automation / Collaborative Manufacturing

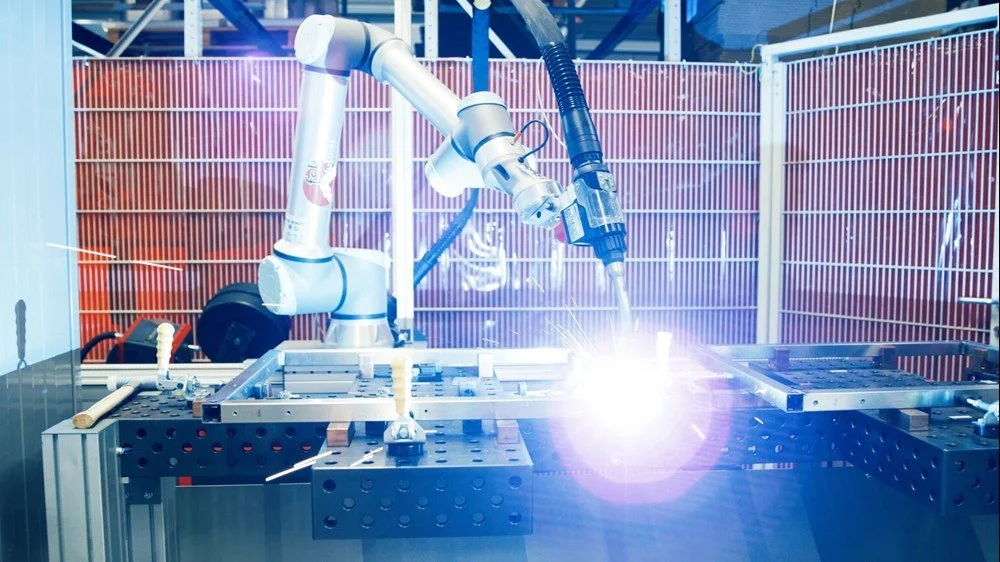

Over the last few years there has been a push for automated capabilities in handmade manufacturing scenarios. These concepts and tools have been applied in many areas and industries including welding, packaging, painting, mechanical assembly, and even quality control validation.

The idea is to offload repetitive tasks to equipment like robot arms. This will reduce operator stress and potential injury while increasing quality and throughput on mundane tasks. Even without full automation, you can streamline your processes. Collaborative manufacturing can help automate “what’s dirty, dull, and/or dangerous”.

This approach uses specialized versions of equipment which is normally used in fully automated environments, but which is specifically designed for collaborative manufacturing.

Cobots

One of the most popular tools for collaborative manufacturing is a collaborative robot, or cobot. Cobots can give your operators the tools to do their job more safely, easily, and repeatably without having to invest in a fully automated manufacturing system.

Collaborative robots are conceptually similar to a fully automated robot arm you’d seen in many manufacturing facilities. The major difference is their speed and power is limited so they can co-exist in the same workspace as a human operator while taking on some of the operator’s tasks.

Common applications across the “dirty, dull, and/or dangerous” spectrum include:

Welding

Palletizing/Packaging

Inspection

Machine Loading / Unloading

Pick and Place Operations

Cobots, such as the ones produced by Universal Robots, have been used in all of the above scenarios. These applications require specific tooling on the robot, and robot programming for each task. But, they can aid operators in these tasks with minimal cost compared to fully automated robot solutions from Fanuc for example. Cobots are also safer in close proximity to operators as they operate at lower speeds and torques to prevent injury to anyone nearby.

While these tasks could also be moved to a fully automated setup, you can gain some of the benefits of automation by using cobots at a much lower cost. Using cobots also allows you to retain your staff along with their knowledge and experience to help your company and team do what they do better.

Digitized Assembly Lines

Another collaborative manufacturing tool gaining marketshare is Tulip. While you can certainly build all of the functionality into a SCADA system like Ignition for a digitized assembly line in a larger facility with more automation, Tulip is geared towards companies who are mostly hands on and can’t easily map their process to full automation.

Tulip has many features geared towards improving quality and throughput. These include—but are not limited to:

Digital Work Order Instructions

Pick and Put to Light Systems

Digitized Logbooks

Operator Training

Visual Quality Inspection

If cobots can give your operators a physical extension of themselves, Tulip is a way to expand their mental capacity using technology.

Digital Work Order Instructions provide a real-time framework of how to accomplish tasks, assemble units, or perform inspections. They can give your operators a checklist, ensuring complex operations are performed in the correct order with a record.

Pick and put to light systems give your operators an exact location and quantity requirement when picking or placing parts for various operations, reducing errors in counting or part selection.

Digitized logbooks Quality control data from further on in the process can even be correlated with digitized logbooks to fully understand the work your operators are performing.

Tools like Tulip are branching into quality systems by providing visual quality inspection powered by machine learning algorithms. This allows you to use machine vision systems to streamline your quality control inspection process. Along with the training and work order instructions tools, you can provide immediate feedback to your operators in the event of a quality issue.

Combining tools like Tulip and cobots with your processes can provide huge gains in production, reduce rework, and develop a well-trained and highly efficient workforce with minimal technology integrations required.

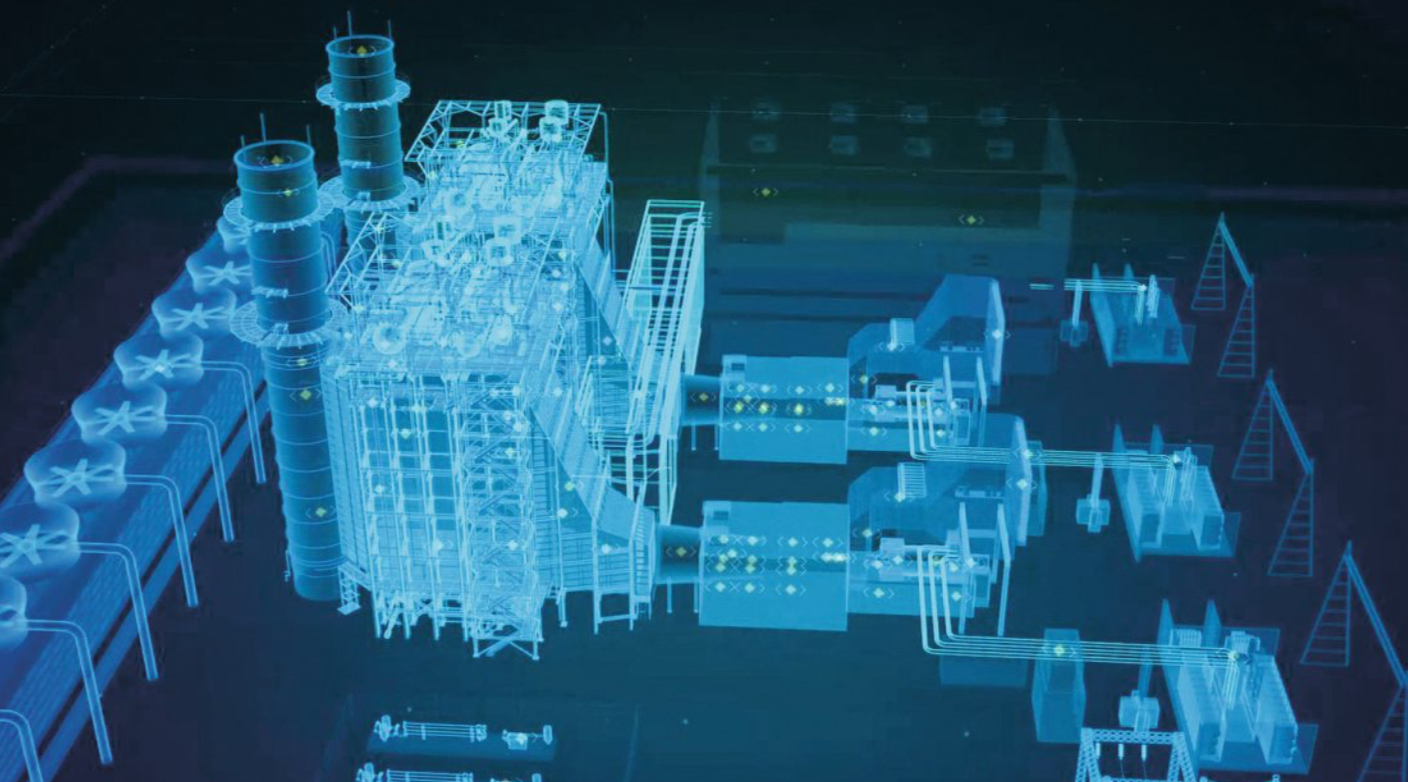

Digital Twins

Another very popular tool—at least from a marketing perspective—is a digital twin. Digital twins can take on many forms, they can be a software simulation of a manufacturing process, or a duplicated hardware setup which mimics PLCs and network infrastructure. They could even be a standalone SCADA system or a fully virtual factory floor you can traverse with a virtual reality headset.

The reason digital twins are exciting is their similarity to flight simulators for training pilots. You can set up interesting scenarios to test operators’ knowledge and run training exercises without having the cost of mistakes in the factory floor. It is cheaper to blow up a video game plane an infinite number of times while learning how to fly than it is to lose a real airplane once. After training with a simulator, moving to the real thing can be a much easier process than starting on it from scratch.

Digital Twins do have some hurdles though. Writing the simulation without something like Simulink to build out a model of your system can be a difficult task. Building a true digital twin with a full suite of hardware behind it is a costly endeavor and can limit the overall training you can do. Finally, most times when a system is running it will do the same thing every time until something breaks. Figuring out what might break and when is the reason companies like Corso Systems exist in the first place. Many times it is more interesting and educational to solve the real world problems as they arise than to play a video game version of your factory.

We will dive into Digital Twins more in the future. While we are just skimming the surface here, we would be remiss if we didn’t include digital twins in a collaborative manufacturing technology post.

Wrapping Up

Everyone wants the highest quality artisan goods, handmade by an expert craftsperson. People also have become accustomed to being able to buy just about anything you can imagine—and to have it show up on their doorstep in two days.

By leveraging technology as a tool for craftspeople to take out some of the drudgery from their work, we can start to see the benefits of both worlds. The artisan can do what they do best, and take away any pieces of the puzzle that may distract them from their job. Tasks that do not impact the overall handmade qualities can easily be offloaded to cobots or other technology tools allowing the work that matters to shine through.

Think about it this way: sometimes you want McDonalds, and sometimes you want an incredibly well crafted meal. Most of the time you want something in the middle. Using collaborative manufacturing technology gives you that middle option, at least in the manufacturing sense.