Integrating Node-RED and Ignition

In the world of IIoT, Node-RED is one of the most ubiquitous and easy to use tools available. It allows you to build a program graphically, integrate with any number of APIs, custom libraries, and web services—and it can run on a server, a Raspberry PI, or even on an Opto22 Groov Epic PLC!

As we move deeper into our Lean Manufacturing theme, it seemed fitting to do a brief how-to on integrating Ignition’s Perspective module with a Node-RED system.

Why Integrate Ignition with Node-RED?

First of all, why should we integrate Ignition with Node-RED? Since many IoT devices are built to work with Arduinos or Raspberry Pi—and most industrial hardware and software is designed to talk to industrial hardware—we need something for getting electrical signals where they need to go. Let’s say we want to get information from an Arduino and trigger something on a PLC. We could set up some relays and wiring to get the +5VDC signal from the Arduino to trigger a +24VDC input on a PLC, or take an analog output from a GPIO pin on a Raspberry Pi with some converters and get it into a 4-20mA signal on a PLC. But, why bother with all of that when we can do it in software? It will save us time, involves less equipment to maintain, and has less risk of completely frying our hardware.

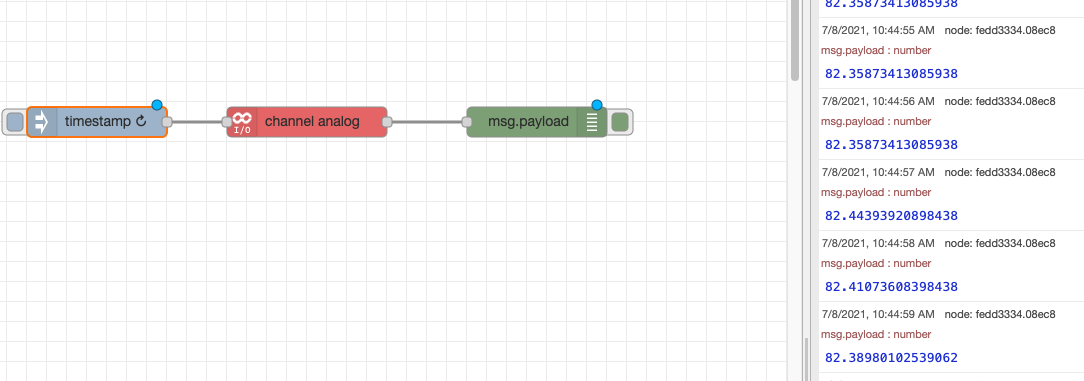

Node-RED can take the signals from the I/O on the edge devices, parse and massage it, and then send it to our PLC hardware and SCADA system via a number of channels. Node-RED supports MQTT, Modbus, Ethernet IP, and many other industrial protocols. It even has BACNet drivers!

This bridge between SCADA and non-Industrial hardware is more important than ever with the advent of Ignition Maker Edition and some of the tools included in the home automation Ignition Exchange package. These tools move Ignition into the realm of the maker community, already familiar with non-Industrial hardware, and it bridges the gap between the two worlds.

Exposing Innovation

Exposing Ignition to maker hardware like Raspberry Pi also enables low cost, high functionality technology at a very low price point. This will bring more innovation to the industry by allowing more people access to the tools they need to implement new technology.

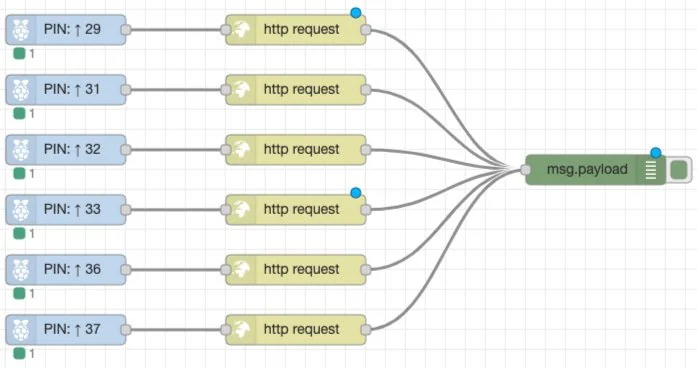

One example of this concept is a Pick to Light system. While we could use a PLC, run a lot of wire to a bunch of expensive panel mounted LEDs and buttons, and then write a lot of PLC code, if we use a Raspberry Pi with Node-RED we only need a Raspberry Pi, a strip of LEDs, an ethernet cable and three wires. We could even run Ignition on the Pi itself and not even need the ethernet cable if we wanted to really pare it down.

First, we will set up an HTTP node in Node-RED to receive a signal from Ignition, then call it from Perspective using a system.net.http call. We will then send over the relevant data, send Ignition back a response from Node-RED, and let Node-RED handle the LEDs through the Raspberry Pi GPIO pins.

We could package this as a demo system, and when the customer likes what they see, we would grab a fresh strip of LEDs to meet their shelving layout requirements, and leave the hardware with them for a test run.

The True Game Changer

By opening the industrial automation world to the maker community—and exposing lower cost hardware to Ignition—we give an entirely new group of people the tools to learn, grow, and bring their experience to our space. This can only help us grow a more diverse community, allow more companies to benefit from new technology, and make it easier than ever to improve the manufacturing world across the board. Are you ready to get started with Node-RED at your facility? Contact us!