Digital Work Order Instructions

An important factor for Lean Manufacturing is ensuring that operators have what they need when they need it. This includes information and training. In cases where operators may be assembling equipment, packaging orders, or performing validation testing or quality checks, it is important they have the necessary instructions.

One easy way to empower people is to give them Digital Work Order Instructions.

Think of this like an on-demand “How-To” manual. Digital Work Order Instructions can even be used as a gating tool, requiring data to be entered before additional steps are displayed. This is no different than putting a lot in the warehouse on hold until its results come back from the lab, except on a much smaller and more expedient scale.

Just In Time Instructions

The best digital work order instructions give the operator small steps with pictures and text (or video if that is helpful). Multiple image angles may be beneficial if operators are assembling a complicated jig.

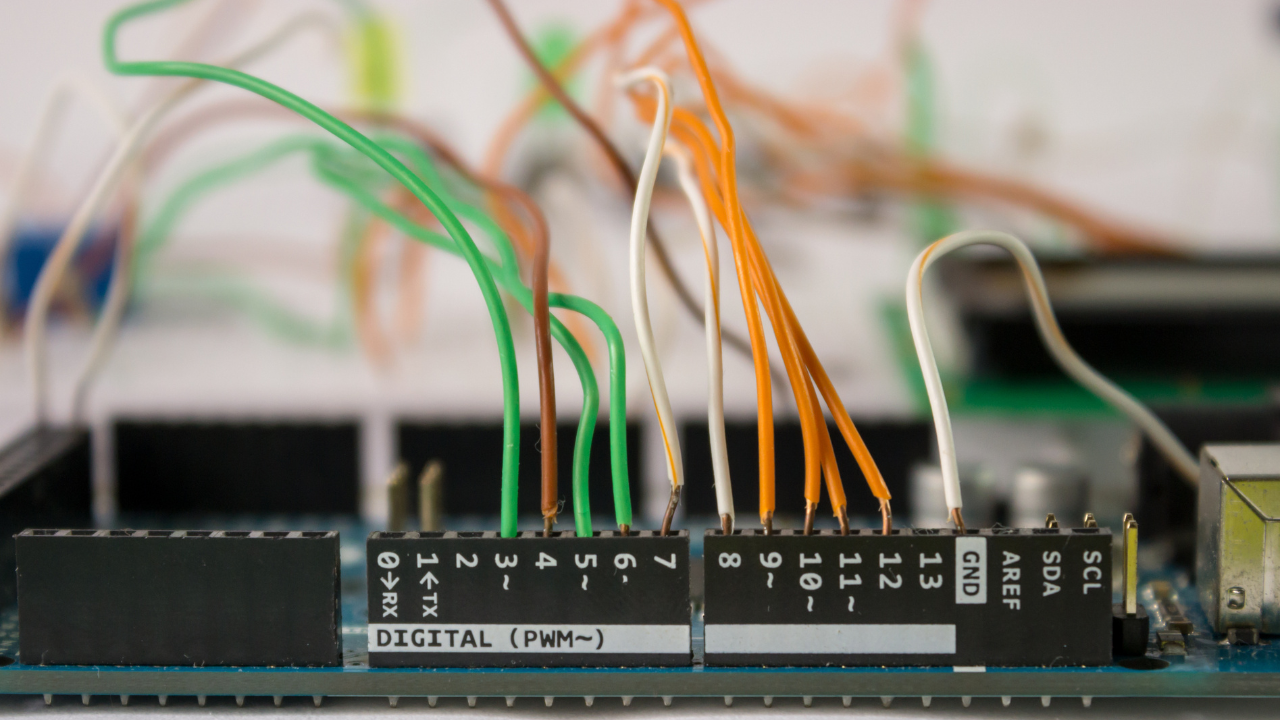

Example: an Arduino circuit assembly instruction document.

The image above clearly shows where everything needs to be plugged in. In the image, the wires are also pushed out of the way to remove any confusion.

Using an image like this gives the operator a concrete example that they can check their work against. If their setup looks identical, then everything is good to go. A more complicated Digital Work Order Instruction system may have the operator take a picture of their setup to store along with the lot number records. If a check needs to be done to validate the work—or verify the quality of the part—they could enter this information in before the system allows them to move onto the next step.

Real World Examples: Digital Work Order Instructions

Examples we have implemented in the past include:

A refrigeration system assembly guide, requiring wiring, pressure, and temperature checks by automated equipment to verify the parts before they moved on for further processing

CNC Machine loading instructions, with sensor checks on part dimensions after machining

Embedded circuit programming systems for a variety of boards, illustrating how to connect them to the programmer, along with validation and printed barcode labels once parts were programmed

Recipe instructions for chocolate manufacturing, with ingredient validation using barcode scanners and a load cell to verify weights added to the mixer

Solder manufacturing recipe instructions and quality control validations at multiple steps in the process, including weight and temperature checks from automated quality equipment

Why Should You Use Digital Work Order Instructions?

Digital Work Order Instructions are a powerful tool for any lean manufacturing operation. They can help reduce rework and operator fatigue by empowering operators with the tools they need to do their job effectively and efficiently.

Want to learn more about Digital Work Order Instructions? Reach out to us and let’s start a conversation!

Updated - 2/9/2023