Data Center SCADA with Ignition

Startled awake from a dream by a dinging phone was enough to make Olivia’s stomach drop. Nothing good could be pushing through do not disturb at 2:47AM as she fumbled for her phone on the nightstand. As she got her bearings, the phone illuminated her dark bedroom with an urgent alarm: Critical fault detected in Cooling Zone 3 - Temperature threshold exceeded. As the lead facilities engineer of a massive data center, she knew overheating in any zone could cascade into a catastrophic failure affecting thousands of servers and their clients' operations.

Olivia rolled out of bed and immediately opened her laptop, her fingers moving with muscle memory to launch the Ignition SCADA system used to operate the data center’s facility management system. From her house thousands of miles away from the endless server racks, Ignition’s real-time dashboard painted a clear picture of the potential crisis. Temperature readings in Zone 3 were climbing steadily, 78°F and rising in a space that should never exceed 72°F. The affected zone housed servers for three major financial services clients whose trading algorithms couldn't afford even seconds of downtime.

Digging into the equipment status screen, she could see Cooling Unit 7 had failed, and its backup unit was struggling to compensate. She quickly pulled up the unit's maintenance history, cross-referenced recent performance data, and identified a clogged filter which had been flagged for replacement just last week. This clogged had likely caused the primary unit to overheat and shut down automatically, just as it was designed to do.

Within a few minutes, Olivia was able to remotely activate an auxiliary cooling system, adjust airflow patterns through automated dampers, and dispatch an on-site technician with the exact replacement parts needed to resolve the issue. By the time her pot of coffee had finished brewing, Zone 3's temperature stabilized, and the servers never came close to catastrophe.

Note: All of the features detailed below are included in our Data Center Power Pack. We developed this Power Pack to simplify the process of getting equipment connected and commissioned for any data center application.

Critical Temperature Monitoring

One of the most important aspects of managing data center operations is maintaining the temperature and air quality in the server rooms. Thousands of servers in a forest of racks generates a lot of heat. Air Handling Units (AHUs) installed in the data center keep air cool air flowing, manage humidity and filtration, and generate alarms if anything is outside of normal operating conditions. Complex systems of ducts and dampers with complex control algorithms move the air to where it needs to go to keep the servers happy.

Ignition simplifies AHU integration through the use of graphical templates and user defined data types (UDTs). UDTs let you build a data map for all of the data available from all of your AHUs, configure historical data collection and alarms once for each type of unit. With the vast number of AHUs in any given facility (and potentially made by different manufacturers and with different use cases and capabilities) you can set up a specific UDT for every make and model of AHU at a data center. In addition each of the AHU types can use a specific graphic template to display the relevant data to your users.

Using UDTs and templates means once an is AHU installed and its controller is on the network, you simply need to connect it to Ignition to access to all of the available data. Then it can be added to a screen with just a few clicks. This approach makes it possible to commission an AHU in a matter of minutes after installation.

Then, all of this data can be trended on demand and integrated into dashboards with a detailed views just a click away.

Power Usage and Quality Management

Beyond temperature control, power management is another critical part of data center operations. Obviously you need power to run the servers and all of the other supporting equipment including AHUs.

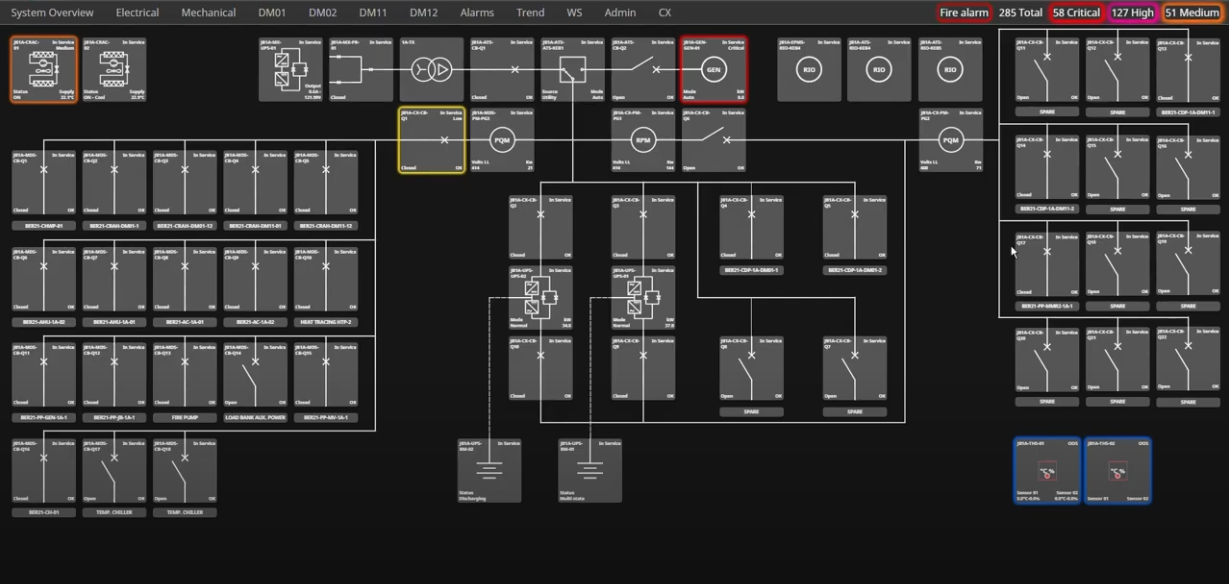

A Single Line Diagram (like the one shown above) is the most common way to display overall equipment health from an electrical perspective. This type of diagram will map out all of your equipment including the status of the switchgear equipment providing power to everything.

In the image above, a blue highlight indicates out of service equipment. Alarm or alert conditions are indicated in red, orange, and yellow.

Clicking on any given piece of equipment in the single line will display a detailed view for current status, any alarms or alerts. With the right integration, you can have the option to operate switchgear equipment as needed.

Power Data Dashboards: basic standard examples

Dashboard with input current and voltage including sparkline charts for historical data

Display for a device with with input and output power gauges

Similar to building dashboards for AHUs, we can also set up templates and UDTs for electrical equipment and power meters. We can also include historical data displays with sparklines or full scale trend charts.

As these items are placed on a single line diagram, you can immediately click on them to see detailed views and dashboards, and all of your historical data can be available the moment the device is connected. UDTs can also integrate alarms and alerts with notifications so they work as soon as the device is online.

Dashboards and Details

Uninterruptible Power Supply (UPS) Dashboard

Dashboards are great for seeing what is happening at a glance. When you need to dig deeper into specific data for a piece of equipment, you will use something like the detail view on the left for a UPS.

These details can give you access to more granular information for troubleshooting beyond the dashboard. These screens can all be configured as popups for viewing multiple pieces of equipment at a time, and you can also use screens to give your team a way to compare data from multiple pieces of equipment together using trends, tables, or key performance indicator (KPI) views like you see on the dashboards.

If you want to dig deep into the root cause analysis of an issue, you can even leverage all of the historical data you’ve collected and use a “replay” feature to monitor any data points. Then you can play back a given period of time with the screens updating as they were during the event. You can even step through time with this replay feature to see what is happened at any given second.

Comtrade Data Integration

Another powerful tool in the Corso Systems Data Center Power Pack is the ability to import and export Comtrade data files. This integration helps you access Comtrade data files from your grid supplier to help identify and troubleshoot issues with the power coming from the grid.

You can also use the equipment on your side of the connection to generate these files giving you access to powerful analysis tools for all of your power monitoring equipment.

Wrapping Up

Data centers are critical infrastructure. Keeping them operational helps keep society functioning and ensures everyone has access to the tools they need to do their jobs, enjoy the internet, and keep important data for manufacturing operations readily available.

Ignition is an extremely powerful tool especially for data centers, given how easy it is to deploy a large scale data center’s data infrastructure in a well-tested, standardized way. Our Data Center Power Pack gives you all the tools to get up and running without the headache of developing everything from scratch, with the ability to customize anything and everything to meet your specific needs.

While we didn’t touch on the Cybersecurity considerations data centers need to be aware of in this post, we recommend checking out our Defense In Depth series for more information on managing all of the security related moving pieces.

If you are using another SCADA platform for your data center and are interested in how Ignition can work for you, we also offer a comprehensive SCADA Migration tool and service to help make the process of moving to Ignition as painless as possible, while retaining all of your historical data.

Ready to Power Up Your Data Center with Ignition

and a Corso Systems Power Pack?

Get started today by scheduling a short intro call with Cody Johnson in sales

Or contact us with your project details and challenges