How to ProveIt! with Ignition and Opto22

Sarah walked back to her desk with a familiar mix of excitement and apprehension. She had the feeling that comes with getting a project that could either be a career-defining success or an interesting learning opportunity, depending on how optimistic she was in the moment.

Twenty minutes earlier, she was sitting across from the Chief Information Officer, listening to what initially sounded like a straightforward request. "We need to modernize our production systems. The board wants real-time visibility into our manufacturing processes, they want to see something that shows we're not just talking about Digital Transformation, but actually implementing it."

Sarah had nodded along, already mentally cataloging the usual suspects: historians, dashboards, maybe some basic data collection from their existing PLCs. Standard stuff for a manufacturing engineer with many years of experience in process optimization.

Then came the curveball.

"I want you to build this using MQTT and Sparkplug B," the CIO continued. "I've been reading about these protocols, and they seem to be the future of industry connectivity. Plus, our new cloud architecture team is pushing for more standardized communication protocols across all our systems. I’ve even heard about this approach called ProveIt! where a lot of suppliers are building real-world applications instead of just fancy demos to show off what they are capable of."

Sarah maintained her composure, nodding as if she had worked with MQTT and Sparkplug B extensively. But, her mind was racing, she knew MQTT was a messaging protocol, but Sparkplug B was completely new territory. And then, ProveIt! sounded like a new buzzword some tech bros made up because they thought it sounded cool, which was sadly nothing new in the manufacturing world.

Settling into her chair, Sarah cracked her knuckles and opened a new browser tab. She had a connected production system to build, and apparently, she was about to get very familiar with the protocols she'd only heard mentioned in passing at industry conferences.

The irony wasn't lost on her that in order to connect the factory's future, she first needed to connect herself to a whole new world of industrial communication standards. Good thing she'd always been a quick learner!

As she typed "MQTT and Sparkplug B connected enterprise" into the search bar, Sarah couldn't help but smile. Every manufacturing engineer knew that the best projects were the ones that pushed you into unknown territory. This would definitely be an interesting task.

Enterprise Connectivity with MQTT and Sparkplug B

Sarah wasn’t alone in her unfamiliarity with MQTT and Sparkplug B. She’d heard it in passing but never implemented it in a real manufacturing situation. Many years ago, even the Corso Systems team was in this position. We had heard a lot of talk around MQTT in Ignition circles, but it wasn’t until we sat down with Arlen Nipper from Cirrus Link and watched his demo connecting a dozen or more edge devices to an Ignition gateway with a few thousand tags automatically populating the screens in a matter of seconds that we saw the true power of MQTT and specifically Sparkplug B.

The biggest hurdle many people (including Corso in the early days of our MQTT journey) face when considering MQTT is that many PLCs don’t natively support it. So before you can begin to implement the protocol, there’s a number of obstacles to navigate unless you’re already using a controller like an Opto 22 groov EPIC or RIO that already natively supports MQTT.

We are very excited to see Inductive Automation bringing the ProveIt! framework to ICC Level Up in 2025! The concept is pretty simple: set up an MQTT broker that many different vendors can access. Then populate it with data coming from a simulated “digital factory”. Vendors can then use this data to showcase the capabilities of their solutions to simplify using and data where it needs to go.

Not only will this give people already familiar with Ignition a way to see the power of MQTT and Sparkplug B in a close to real life application, it can demonstrate other tools on the market like Canary Labs Historian, Flow Software, and various hardware devices. It will be a live demonstration of how MQTT and Sparkplug B can be used in conjunction with Ignition to expand what your company can do with more connectivity.

Ignition as the Backbone of a ProveIt! Architecture

Starting with ICC Breakthrough in 2023, Travis Cox from Inductive Automation built the first attempt at demonstrating the power of connecting large amounts of data across the manufacturing community using Sparkplug B with the Sparkplug Data Dash. We even used it as part of the Build-a-Thon! This was a great idea and showed off the power of Ignition combined with Sparkplug B to connect a wide array of devices and show some interesting use cases, even though it didn’t seem to get wide adoption and the main display was tucked away near the Ignition arcade upstairs (which meant not everyone at the show saw it).

A big difference for ICC Level Up is that the ProveIt! demos will be in their own room right next to the main stage. This will help keep the focus on the connectivity available with Ignition and all of the solutions available. Everyone can see how Cirrus Link’s modules make it easy to get MQTT data into Ignition and other cloud services like Canary Labs Historian.

Another benefit to this approach is that the data from the MQTT brokers and the overall Unified Namespace specific to the event will use data similar to what may be in your own facility. We’re hoping to see common connected enterprise systems like Overall Equipment Effectiveness (OEE) as well as more complex scenarios such as using actual equipment data to better inform predictive maintenance activities.

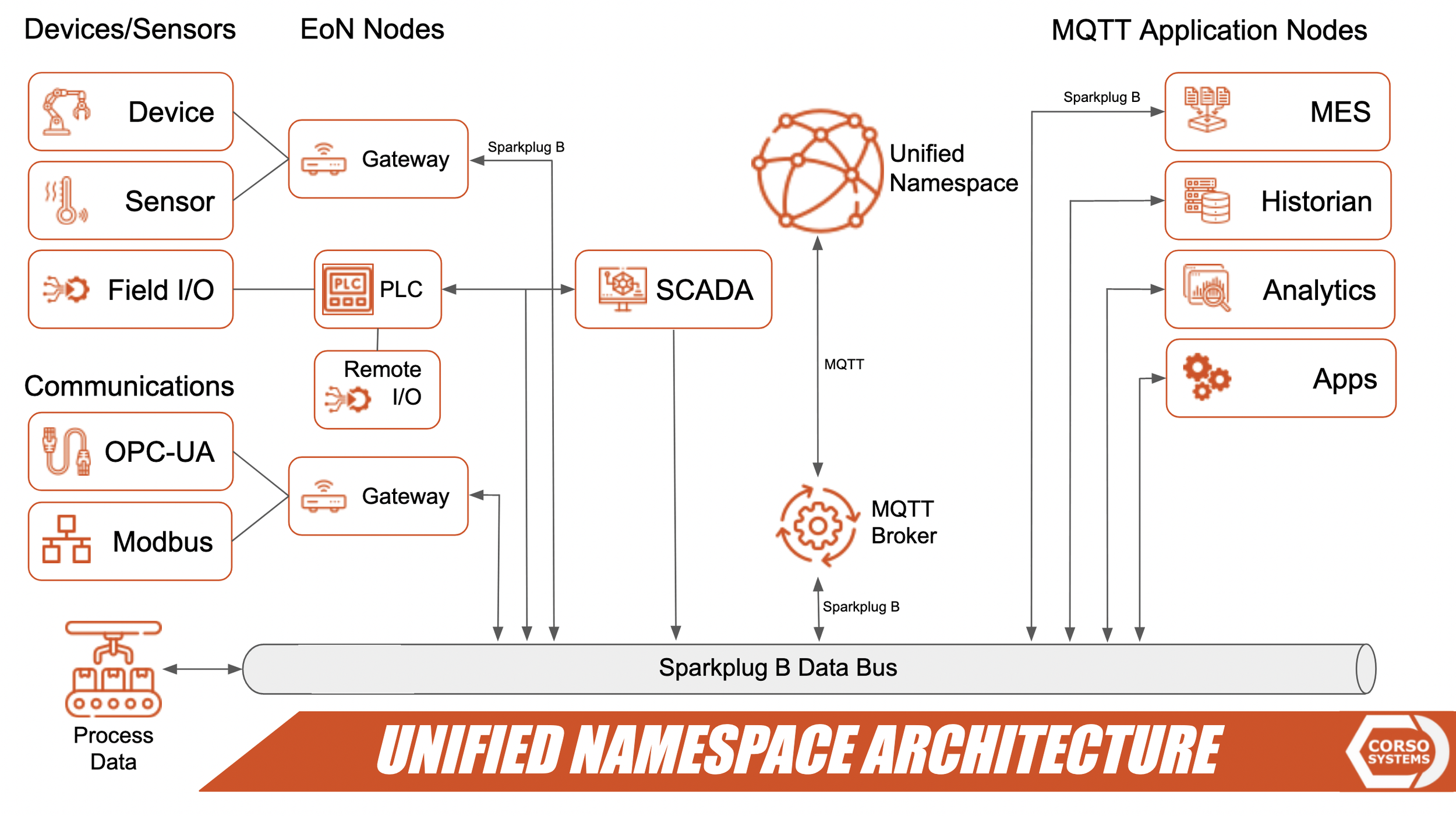

Ignition is a powerful component in the enterprise data space because it can connect to just about any PLC on the market. For devices like Allen Bradley or Siemens PLCs that don’t support MQTT natively, you can use the Cirrus Link MQTT Transmission module to send data from these PLCs to an MQTT Broker. This module allows Ignition to ingest data so that you can use the power of MQTT, Unified Namespace, and systems that rely on MQTT to get more value from it than simply putting the data on a trend screen.

Yes, there are a ton of buzzwords in this article. If you haven’t heard of any of them, or even if you are familiar with them but haven’t yet ventured into the world of Unified Namespace (UNS), we highly recommend checking out our Unified Namespace: The Ultimate Guide ebook. It has everything you need to know to get started in a free ebook format (a low cost Kindle version is also available).

Opto 22 groov EPICs and RIOs Help You ProveIt!

Opto 22 was a very early adopter of everything MQTT, and built it directly into their groov hardware platform. This gives you large-scale PLC capabilities with the EPIC platform, edge of network and remote I/O capabilities with the RIO, and energy monitoring capabilities with the RIO EMU. The RIO EMU and a lot of the concepts you will be seeing at ICC Level Up with the ProveIt! demos are discussed in this excellent talk from ICC 2024 from Benson Hougland from Opto 22 and Rebecca Gillespie from the Indiana Energy INsights program.

The main focus of this talk is on monitoring the energy and power usage of your equipment and integrating it into your overall data connectivity strategy to provide additional context to all of your production data. It includes our free Ignition Exchange RIO EMU Faceplates resource you can use to pull RIO EMU data into Ignition with just a few clicks.

The value of an approach like ProveIt! really boils down to having additional context for the data you are already collecting. Tracking downtime and OEE is a great first step, however it doesn’t explain the entire picture of your operation. Providing context like power usage on top of production data helps to show the overall cost of production over days, weeks, and months. It can help you save big on your utility bills by optimizing production schedules. We’ve even seen examples at wastewater treatment plants where they saved hundreds of thousands of dollars in annual power costs by optimizing their valve manifold control algorithms to reduce the number of times valves open and close daily based on the original control loop tuning.

Using tools like a groov RIO let you add MQTT into your facility’s technology stack with a low cost solution that can connect to your existing devices. This simplifies getting data into the services that need MQTT to function well, and helps you complete an initial proof of concept to help grow your company culture to support connectivity (without investing months or years of effort and millions of dollars in a large-scale deployment). Corso Systems is all about starting with a small project and growing, and the ProveIt! approach is right in line with our beliefs.

Unified Namespaces ProveIt! Right Out of the Box

Unfortunately, the 2023 Sparkplug Data Dash didn’t have a single source of truth for everyone to build on. But, this is easily accomplished with a Unified Namespace. You don’t necessarily need MQTT already in place to build a Unified Namespace, although it does make life a lot easier as MQTT scales to meet your business’ growing needs.

This is where the ProveIt! approach comes into play. Instead of having people throw whatever they want into the data mix, ProveIt! starts with a simulated digital factory using a Unified Namespace. This gives everyone in the ProveIt! showroom access to the same information as everyone else.

The benefit of this approach is you can now easily see how tools like Ignition can integrate with tools like Canary Labs Process Historian, Snowflake, and Flow Software to give your team the best tools to do their job at every level of the organization. Now, instead of having to connect all the dots to show how a Unified Namespace can benefit your company, you can ProveIt! and see it in action with data that makes sense to you.

So, when the CIO gives your team the charge to develop a proof of concept to see how connecting more systems can help make the business run more smoothly, you will have already seen how the pieces can fit together to build the foundation, then add your own unique spin on it as you grow.

Wrapping Up

The hardest part of cutting through all the marketing and buzzwords around digital transformation, Industry 4.0, MQTT, Sparkplug B, digital fabric, and connected enterprises is understanding and envisioning the end result.

You’re not alone if you feel like that is an insurmountable challenge. Starting with the end result in mind and going from zero to a fully connected enterprise can feel like standing at the base of Mt. Everest with the peak far off in the distance. Hearing the harrowing stories of people who have made the climb and are headed home can be discouraging when you are just getting started.

Very few people in the world have walked up to the mountain and climbed to the top with little preparation, time to acclimate to new conditions, and without setbacks. We don’t recommend trying that yourself when it comes to mountaineering or using data and information to make your business run more smoothly.

We’re excited to be a part of ICC Level Up, and see how the ProveIt! concept helps give people a peek into what is possible with Ignition, MQTT, and Unified Namespaces. Sometimes seeing what is possible, even when starting with a small project to get the ball rolling is all you need to take the first step on your journey.

If you need help taking the first step please check out our Unified Namespace: The Ultimate Guide. It compiles everything we have learned helping companies implement these solutions for their teams, and can make the process of wrapping your head around everything that is possible as easy as it can be!

Corso Systems can implement and integrate it all!

Schedule a short intro call with Cody Johnson in sales to get started

Or contact us with your project details