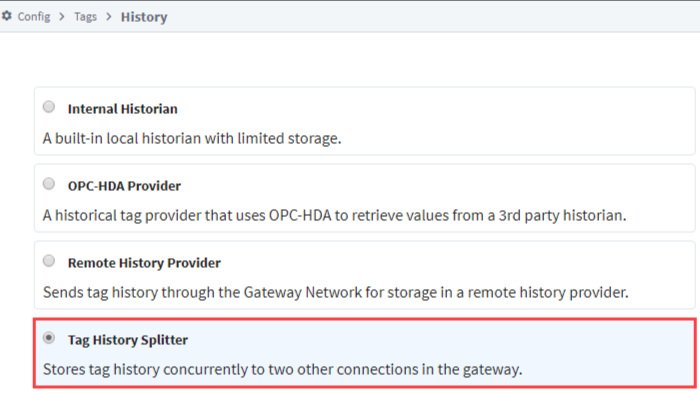

Ignition's Tag History Splitter

Corso Systems shows you how to get the most performance out of Ignition's built-in process historian. On top of the basic functionality you can use the Tag History Splitter to store data to make recent data and long term data easily accessible for different use cases.

Digital Transformation: Data Migration Process and Tools

Digital Transformation processes need to use data in the best possible ways. Is your Process Historian costly or poorly supported by the vendor? Here’s how Corso Systems can help you quickly migrate to a cutting edge, up to date Process Historian.

Canary Historian and Axiom Overview

Did you know that Corso is part of the Canary Labs Certified Integrator Program? Learn why you may want to add the Canary Process Historian, Axiom, and Chirp to your manufacturing project.

Intelligent Automation Series Part 6: Understanding Process Automation Systems

Corso Systems wrote a series about manufacturing information technology for Oil & Gas Engineering Magazine. In the series' final post we discuss how the concept of the manufacturing technology pyramid applies to manufacturing operations with real world examples.

Intelligent Automation Series Part 5: Business System Integration

Corso Systems wrote a series for Oil & Gas Engineering Magazine detailing the technology involved in running modern manufacturing operations. This part of the series discusses business information system integrations to connect the top floor to the shop floor and give your team full visibility into your operation.

System Migration: Wonderware to FactoryTalk Historian

Corso Systems recovered and migrated data from a failed server at a diatomaceous earth processing company which had two facilities with Wonderware Historian installations on older hardware. We migrated the Wonderware Historian configuration to FactoryTalk Historian with no data lost during import and migration.

Remote Viewing Application

Corso Systems describes Remote Viewing Applications, and how to make them secure. Learn about why you may want to choose a Remote Viewing Application to view your real time process from anywhere in the world!