The 4 Biggest Benefits of a Unified Namespace

Though Cirrus Links’ MQTT Modules for Ignition having been “out in the wild” for at least ten years now, recently there is a lot of talk about using Unified Namespaces in the context of the Ignition SCADA platform.

While you don’t need to use Ignition to build a Unified Namespace, it is a great tool to for implementing one. While we can talk about the technical implementation details of Unified Namespaces until we are blue in the face, let’s first discuss some of the reasons you might want to use one, and how a Unified Namespace could benefit your company.

Authority

A main benefit of using a Unified Namespace is that it is a single source of truth for all the data regarding your business. This includes plant floor data, production information, production schedules, inventory, work orders, recipes, and many other processes that manufacturing companies use to run their operations.

In the world of Industry 4.0 where everything is now connected and integrated much more than ever, it is easy to duplicate data across many different integrations. This duplication can lead to potential problems when data in one system is out of sync with the same data in another system. While this can happen for many reasons, it is usually more common when you have more integrations between systems.

Using a Unified Namespace reduces these risks because you integrate all of your tools and technology with the Unified Namespace instead of with each individual system. Then, when a data point is updated in the Unified Namespace, it is updated for any and all devices or software tools which are concerned with that data.

Applying a Unified Namespace to your company’s data will give you the peace of mind that all of your data is available to anyone and anything which might need it. Plus, you will not need to deal with stale or out-of-sync data. This will be true across the entirety of your business that is integrated with your Unified Namespace.

Maintainability

Another awesome benefit to using a Unified Namespace is the maintainability it provides compared to traditional integration methods. Traditionally, integration would be done in a linear way:

PLCs<->SCADA<->MES<->ERP<->Warehouse ManagementUsing a Unified Namespace allows you to integrate each individual tool to the Unified Namespace directly. Now, to get the data from your PLC to your ERP system you only need to make one hop using a Unified Namespace, instead of three as in a traditional integration.

This 1:1 mapping between devices and data is much easier to maintain than a typical integration scenario. If you need to update the flow of data, the name of a tag, units on a value, scaling—or many other subtle tweaks you uncover during the life of a system—you now only need to change them in one location for every integration to be updated at the same time.

Scalability

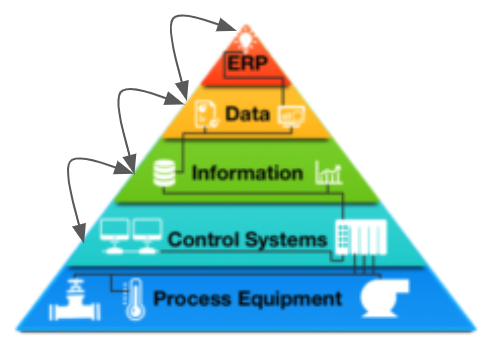

Unified Namespaces also allow you to easily scale the size and scope of your systems. In a traditional model, you would need to add various translations and integrations for your data to move between levels. For example, when using an ISA-95 or Purdue model for your data (with each level representing one integration) you would need to add three different translations or hooks into your data to go from your PLCs to your ERP system.

This not only increases the amount of work when adding a data point to your integrations, it also adds many layers of complexity to your system. As you add more nodes to your integration graph, you will need to continue managing all of this complexity moving forward.

In addition to the labor for adding and maintain these connections and translations, you will be sending the same data to multiple systems multiple times which will increase your overall network bandwidth. In a world of cloud-based data lakes, this increase in bandwidth can directly add significant cost of ownership to your system without adding any value.

By using a Unified Namespace instead, we get access to all the data across the entire system with only one level of translation required to go from a local or domain namespace to the global or Unified Namespace. This reduces the amount of effort and bandwidth required for adding new integrations to the system. You can use the Unified Namespace to scale your system to any size you need.

Modularity

By using a Unified Namespace, you will have a completely modular system that anyone can integrate with by using the Unified Namespace specification for your organization.

When you find new technology you want to integrate in the future, or when swapping OEM providers for some of your equipment, the new items can directly integrate their system with the Unified Namespace without having to bring in developers or engineers from each level of the company to implement data translations.

A modular approach also lets you add data to the Unified Namespace so it is available when you need it in the future. However you won’t need to immediately implement any domain level integrations like pulling in downtime reasons into an OEE tracking module in the MES layer. Those tasks can wait until you are ready to use them. This means you can have access to all of your data up front. When you need to use your data, you’ll be able to dig into what you need then, and not all at once.

As we have seen with the Ignition architecture as a whole, modularity is a great feature in the manufacturing world. Applying the same concept to your data can reap huge rewards as your system grows and expands.

Wrapping Up

Using a Unified Namespace for your manufacturing operation can bring many benefits. As we outlined here, scalability, modularity, maintainability, and authority are some of the biggest ones.

With a Unified Namespace, you reduce the amount of effort required to add new systems to your technology infrastructure. You can easily offload the work from your internal teams to your suppliers where possible since they can directly integrate their systems with the Unified Namespace. Your system can scale to meet any sized challenge you have—or whatever you need data to solve—as the Unified Namespace acts as the single source of truth for understanding the state of your entire business at any given point in time.

Using tools like Ignition from Inductive Automation and Cirrus Link’s MQTT Engine and Transmission modules make implementing a Unified Namespace simpler than ever before. If you have any requests for future topics you would like to see on the Corso Systems’ blog, or have questions about how to use a Unified Namespace at your organization please reach out and let us know!