Improving Energy Efficiency with Ignition and Opto 22

Energy costs are significant to any manufacturing operation. While these costs usually apply to electricity and natural gas, they may also include generating other facility utilities like compressed air and steam.

Monitoring energy use provides a foundation for understanding your equipment with the highest energy consumption. By combining energy monitoring with data tracking on overall performance, you can make smart, data-driven decisions for enhancing operational efficiency and reducing costs.

Since many large-scale manufacturing companies that could benefit by reducing their energy consumption (even by 1%) already use Ignition as their SCADA system, they have a perfect opportunity. By adopting an overall energy efficient mindset, they can reduce overhead costs and their environmental impact.

In this post, we’ll examine how manufacturing companies can leverage energy monitoring and optimization.

What is Energy Monitoring?

Energy monitoring includes tracking and analyzing equipment and processes within a manufacturing facility to determine their energy consumption. Facilities can monitor everything from large machinery all the way down to lighting and heating systems! With these insights about when/where energy is used, you can then identify inefficiencies and areas for improvement—and savings.

Why Energy Monitoring is Essential

Cost Reduction: Energy is a significant expense in manufacturing. By identifying energy-intensive processes and implementing more efficient practices, companies can significantly reduce energy bills.

Enhanced Operational Efficiency: Understand your energy usage patterns to optimize operations. Example: scheduling high-energy-consuming tasks in off-peak hours can reduce costs and strain on equipment.

Environmental Responsibility: Reducing energy consumption aligns with global efforts to lower carbon footprints, an increasingly important factor for businesses and their stakeholders.

Compliance and Reporting: With growing environmental regulations, energy monitoring helps ensure compliance and simplifies reporting requirements.

Preventative Maintenance: Tracking energy usage across your facility you will show you when to perform preventative maintenance. When bearings begin to go bad, or if you observe higher costs for steam generation, you’ll know this could indicate necessary maintenance for your equipment and pipes. Catching these types of signs early will save you money over the long term.

5 Steps For Implementing Energy Monitoring

Begin with a thorough energy audit to assess current energy consumption and identify key areas for monitoring.

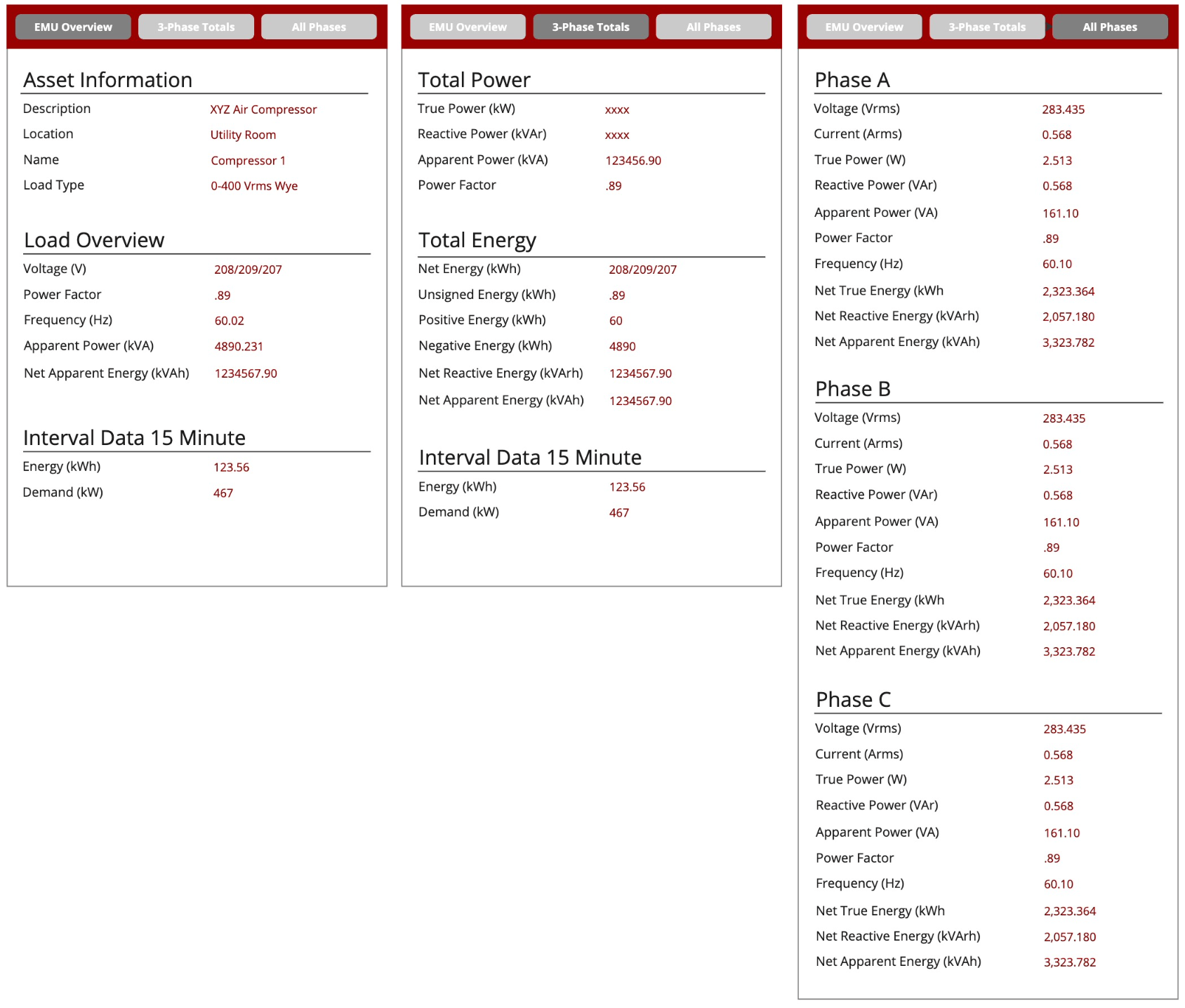

Invest in the right energy monitoring tools and software for tracking real-time energy use while providing actionable insights. One excellent tool for this job is the groov RIO Energy Monitoring Unit (EMU) from Opto 22. This powerful device interfaces with your existing equipment loads and automatically generates the relevant information for monitoring utility usage across your facility.

Ignition also provides an incredible backbone for tracking and managing your data. It also integrates seamlessly with Opto 22 hardware to give you all the analysis tools you need to better understand your current energy forecasts. We even released a free resource on the Ignition Exchange for integrating a groov RIO EMU with Ignition!

Train your employees to understand the importance of energy efficiency and how they can contribute to reducing energy use.

Regularly analyze the data the system collects to identify trends, inefficiencies, and potential improvements. Implement changes based on this analysis.

Energy monitoring is not a one-time activity. For best results, continuously assess and refine your strategies for improving energy efficiency at your facility.

Common Success Stories

With Corso Systems’ help, many manufacturing companies have successfully implemented energy monitoring. One of the most common insights we’ve found is that a significant amount of energy is consumed during non-operational hours when equipment is left on standby. The companies who address this situation have easily and significantly reduce energy costs. As an Opto 22 partner and premier Ignition integrator, Corso Systems has the best technology for energy monitoring.

Another energy-cost-saving example we’ve implemented are low fire modes for processes requiring natural gas to keep a furnace hot overnight during non-production hours. At the end of production, the low fire mode is activated to maintain a lower overall temperature of the furnace overnight. This results in less gas usage. An hour before production begins on the next day, the furnace is in “Preheat” mode to bring it up to temperature for that day’s batches. By the time operators are ready to load parts, the furnace is ready—and they have saved a significant amount of energy resources overnight.

The Future of Energy Monitoring

Energy monitoring will continue to get more integrated and automated as technology advances. Industrial Internet of Things (IIoT) devices and smart sensors will play a crucial role in providing real-time data, making energy monitoring more efficient and insightful.

Eventually, these innovations could lead to full integrations with utility companies with Distributed Energy Resource Management Systems (DERMS). This will allow smart meters at the facility level to communicate with the electrical grid, helping the electricity provider manage overall the load on the grid and generation systems. These systems can create opportunities for pricing and agreements for large energy users integrated with utility providers. For example, utility providers could throttle usage during peak hours in exchange for price breaks.

Wrapping Up

Energy monitoring is a vital tool for manufacturing companies looking to improve efficiency and reduce costs. By understanding and optimizing energy usage, manufacturers can not only save money but also contribute to a more sustainable future. The key is to start small, continuously improve, and always be guided by the data.

Ready to reduce utility costs & environmental impact

—while improving efficiency?

Schedule a 15 minute intro call with Cody Johnson in sales to get started ASAP