Control Panel Excellence: CODESYS Runtime and groov RIO

The Corso Systems team recently shipped our first control panel running an Opto 22 groov RIO with the CODESYS Runtime Engine. Now that groov RIO is CODESYS Runtime Engine ready, its no longer just a robust remote I/O device—it’s a fully functional PLC!

We hope to use this relatively new functionality on more projects soon and wanted to highlight our experience. We’ll even spill the beans on what we don’t like about this approach!

groov Manage = Fast Integration

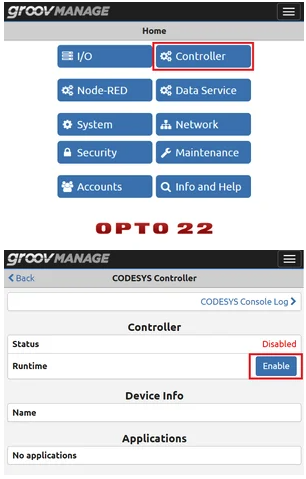

Setting up the CODESYS Runtime Engine on the groov RIO is a very quick process:

Log in to the groov Manage page

Navigate to the right menu

Enable it, and you’re off to the races!

Of course, to actually use the CODESYS Runtime on the groov RIO, you also need to setup the CODESYS IDE on your computer, create a a new project, and add in the right libraries for integrating the groov RIO hardware into the mix.

The best way to get up and running with the CODESYS Runtime Engine on a RIO is to run through Opto 22’s excellent Online Training course “Creating Control Programs with CODESYS”.

One note about this training: after installing the Opto 22 library in the CODESYS IDE, if you suddenly notice a ton of errors in your project, look in the toolbar of the Library pane for a “Download Missing Libraries” button. Click it and follow through with the library installations.

Since this project will also be integrated into our favorite SCADA platform, Ignition, we are also taking advantage of the built-in OPC-UA Server running in the CODESYS Runtime Engine controller. This allows us to map an OPC Server Connection in Ignition and have access to all of the tags we’ll set up in CODESYS.

All-in-One or Keep It Separated

When implementing automation and SCADA projects, we’re often asked if we recommend keeping everything in one tool, or if integrating multiple tools is the better choice.

A critical challenge for this particular project was that it would need to control Allen Bradley Powerflex 525 VFDs over ethernet. While it would be amazing if the RIO could import an EDS file for the drive and communicate natively, we were still left with a few of options:

First option: we could simply connect the VFDs to the groov RIO with the standard I/O. Although, this choice would also require adding a third RIO to the panel for additional I/O points.

Second option: we could set up a flow in Node-RED to handle communication with the drives, then interface back to the RIO’s internal logic.

Third option (the solution we chose): apply the CODESYS Ethernet/IP Scanner to our project, and work with everything directly in CODESYS.

The CODESYS-only route was also the most similar to how we implement the project in an Allen Bradley PLC. We would set up the VFD as a remote device in the PLC, make the tags available, and set values in the logic as needed.

Another big benefit to the option we chose is fewer moving parts. Now, when we need to add another VFD to the system in the near future, we’ll only need to look in one place.

Generally, it makes the most sense to use as few tools as necessary. At the very least, this will reduce a project’s long term maintenance requirements.

Multiple RIOs in One Panel

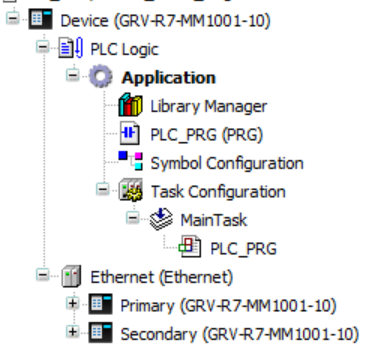

Another nice feature of using groov RIOs along with the CODESYS Runtime Engine is the ability to add more RIOs to the project as remote I/O devices—without having to install the CODESYS Runtime Engine on each of them.

To meet the customer requirements for this project, we needed to use both Thermocouple Inputs and Discrete Outputs across the I/O of two groov RIOs. We are running the CODESYS Runtime Engine and the Ethernet/IP Scanner on the Primary RIO. The second RIO is configured as a remote I/O device.

This approach gives us access to all of the channels from both groov RIOs in the CODESYS Environment for logic purposes. We can also send data up to Ignition so that operators can view the system.

Wrapping Up: Pros and Cons

Time to keep it real. Although we absolutely love working with all of the products from Opto 22, and have grown to enjoy CODESYS as a control platform, we do have some constructive criticism for this overall setup in an ideal world.

First, many of our engineers use Mac OS, so using PLC software that is Windows-only can be mildly obnoxious. For reference, most (if not all) PLC software on the market is Windows only, so we’re forever required to have a second computer or using a virtual machine. This is less of a knock on CODESYS, rather with technology in general!

Understandably, the groov RIO can only pack so much into such a small—yet extremely powerful—package. That said, even though there are 10 channels, you may not be able to use all 10 of them on each RIO depending on the signals you need. In our example project, we were limited by the fact that the thermocouple inputs and discrete outputs can’t be mixed on Channels 0-3. Overall, this was not a problem, since we already needed two units for this project. But, the type of signals you need will be important to consider when you’re planning out a project.

Using groov RIO units along with CODESYS gave this project an incredibly short timeline and surprisingly low cost. Other brands of PLC hardware would have cost significantly more than the two groov RIO units since we needed thermocouple signals.

The CODESYS IDE is free. However we did need to purchase a license for the CODESYS Runtime Engine as well as the Ethernet/IP Scanner. Still, this came in well below the hardware costs from other vendors for the same functionality.

A very big advantage of choosing Opto22’s groov RIO hardware was that even late into 2023, we were able to place an order for the hardware we needed, and it arrived just three days later. Many other hardware vendors in the marketplace right now can’t do this. With the fast delivery—along with amazing support from the Opto 22 team, and we were able to hit a home run with this project!

Ready to learn how we can deliver a similar solution for your business?