Historical Playback in Manufacturing

One powerful feature of Digital Twins is the ability to run simulations without impacting production. If you are considering making a change to the process, you can make it on the Digital Twin, then run your process simulation to see the results. Depending on the granularity of your simulation, you can gain some really interesting insights into what might happen if you make these changes to your process in the physical world.

The other benefit of using Digital Twins comes from the ability to use them as a training tool. Your operations staff can use the Digital Twin to learn how to use the process. They can also train by observing what actually happened during a given scenario using historical data—with Historical Playback.

What is Historical Playback?

Historical Playback is a pretty basic concept. With the historical data you are already collecting from your process, you can stream that data back into your Digital Twin and you rewatch what happened at any given point in time.

Much like sports teams recording their games and watching them back to learn what they could do differently next time, you can use Historical Playback as a way to calibrate how your team is performing.

Why is Historical Playback Useful?

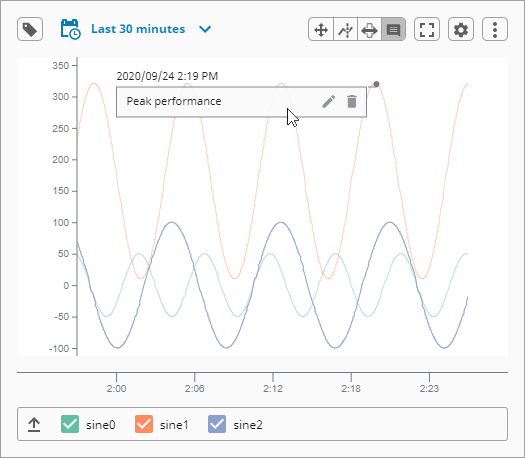

Historical playback is useful for a number of reasons. First, it gives you a realtime view of how your process was functioning at a particular point in time. While you can certainly do this sort of look back using trending tools and reports, it will require a bit of work on your part to get a full picture of everything that was happening.

For example, if you have a trend pulled up on a screen, it can be cumbersome to see what alarms might have popped up during that same time period. Unless you are looking at every tag on a trend you would have on a SCADA screen, you might also miss key information about a particular instrument or piece of equipment.

Using trend screens also requires that your operators have detailed process knowledge, so is not the best training tool for new operators.

On the other hand, combining Historical Playback with your current SCADA screens can be an excellent training tool. Your operators can see the screens they will be using on the plant floor with the values changing as if they were running the process. Alarms will pop up as they will in actual operation, and you still will have access to the trending tools for a more data analysis focused approach.

You can also combine Historical Playback with simulated scenarios if you want to train operators on a particular operation that may not have happened before. Simply generate a historical data set using your simulation engine and run that through the digital twin as if it had actually occurred.

Historical playback presents a lot of opportunity for training. You can train operators on how things should operate, easily point out mistakes that happened during a production run, or even put them into scenarios that test their knowledge of the system as a whole.

How To Implement Historical Playback

The first step for implementing Historical Playback is to use a Process Historian to track your process data.

Once the Process Historian is in place using Ignition and the Perspective Module, one easy way to get started with Historical Playback is by using the Historical Playback resource on the Ignition Exchange. This gives you a view you can use as an example to build up your own Historical Playback screen implementation by switching between real time and historical modes.

If you aren’t using Ignition Perspective, another easy way to implement Historical Playback is to set up a duplicate set of memory tags in their own folder in Ignition, then run a timer script to populate those tags with values from the historian. Next, set up a real time/historical toggle on your screens and pass in the tag path including folder for the memory tags when in historical mode, or exclude the folder for real time mode.

Wrapping Up

Historical Playback is a very powerful tool combining the SCADA screens you already have with your historical process data. It can speed up training for new operators by giving them a set of best practices based on how you want the process to operate. And, you can set up scenarios to help them understand how to react to anything your process might throw at them.

We've set up Historical Playback for systems ranging from just a handful of I/O points for a pump station to a full facility with multiple production lines.

To learn more about how you can use Historical Playback at your facility please contact us!